The European MDR: learn from my mistakes

This article is to help you learn the MDR using a product I co-invented and commercialized in 2004, demonstrating how to apply modern MDR regulations. I describe that product in another article. This article helps you learn from my mistakes.

My Mistakes

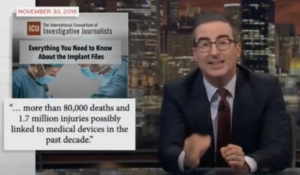

Years later, I would learn that our first medical device eventually caused unnecessary pain and suffering for many patients and added unnecessary expenses to America’s healthcare costs. In this article, I re-analyze our product using modern design controls, risk management, and the European Union Medical Device Regulation; and I share lessons learned in leadership and entrepreneurship.

The background is explained in another article, Medical Devices: learn from my mistakes. I suggest reading that first to understand the product and the loopholes that allowed us to commercialize it without a plan to monitor risk.

The European Union Medical Device Regulations (EU-MDR)

The European Union Medical Device Regulation protects patients by requiring that products continuously improve to reduce risk to patients. If it had been available when I lead development in 2004, patients would not have suffered. Hopefully, this article helps you understand the importance of the MDR and how to apply it at your company.

This application to the MDR is an example, and like any example is not a substitute for in-depth learning. To learn more, search my blog for EUMDR tags, or stat with my article on the EU-MDR Big Picture.

EU-MDR Plans

Example MDR plan

Scope

References

- Product history

- Risk Management Plan

- Produce Design Controls

- Verification & Validation Trace Matrix document, VerVal-TraceMatrix.doc

- Design and Manufacturing Master Validation Plan, DM-MasterVVplan.doc

- Manufacturing processes, ManufacturingProcess.doc

- Manufacturing process validation plan, ManufacturingProcessValidationPlan.doc

- List your quality system policies, standards used or referenced, etc.

Indications for Use

Product Description

Classification

Registration

Clinical Data

- Management of complications of distal radius fractures, Hand Clinics

- Complications following distal radius surgery, Journal of Bone and Joint Surgery

- Complications in distal radius sources, Clinicaltrials.gov

- Complications of distal radius fractures, Hand Clinics

- Flexor tendon problems after solar plate fixation of distal radius fractures, Hand

- A Comprehensive Study of Internal Distraction Plating, an Alternative Method for Distal Radius Fractures, Journal of clinical diagnostic research

Clinical Evidence (summary of clinical data):

Post-Market Surveillance

Post-Market Surveillance Update Report

Risk-Benefit Statement

- If a screw were not inserted flush with the plate, tendons could be exposed to sharp edges and rupture.

- If a surgeon stripped a screw trying to make it flush with the plate, it could become stuck and require additional surgery time to remove and replace the screw.

The added benefit to patients is additional flexibility in treating complex fractures, the ability to pull bones together during surgery, and the ability to avoid fracture lines when inserting screws. These benefits are used to market the Viper system, and residual, additional risks are clearly indicated in written instructions for use and our webpage.

Risk control was applied per ISO 14971, modifying the design of Viper’s screwdriver to minimize stripped screws and adding a drill guide to minimize off-centered holes that could lead to protruding screws. Risk controls are monitored for effectiveness in the Post-Market Surveillance plan, which includes Risk Analysis in the Viper Risk Management Plan.

With current data, the signing team of this document believes that risk has been reduced as far as possible compared to state of the art, and that residual risks of screws protruding are outweighed by additional benefits to the patient of treating complex fractures not possible with other technologies.

Technical Documentation

- Design documents, plate

- See Design Plan, ViperDesignPlan.doc

- Design input.doc

- Design drawing 1.doc

- Design drawings 2.doc

- Design drawings 3.doc

- Design drawings etc.doc

- Verification Test Protocols and Results .doc

- Design documents, screws

- See Design Plan, ViperDesignPlan.doc

- Design input.doc

- Design drawing 1.doc

- Design drawings 2.doc

- Design drawings 3.doc

- Design drawings etc.doc

- Verification Tests Protocols and Results .doc

- Design documents, screwdriver

- See Design Plan, ViperDesignPlan.doc

- Design input.doc

- Design drawing 1.doc

- Design drawings 2.doc

- Design drawings 3.doc

- Design drawings etc.doc

- Verification Test Protocols and Results .doc

- Design documents, system

- System drawings .doc

- Instructions for Use .doc

- Validation test protocol and results .doc

- Manufacturing documents, plate

- See Manufacturing Plan, ViperManufacturingPlan.doc

- Plate Manufacturing process 1.doc

- Plate Manufacturing process 2.doc

- Plate Manufacturing process etc. com

- Plate Manufacturing Process Validation .doc

- Manufacturing documents, screws

- See Manufacturing Plan, ViperManufacturingPlan.doc

- Screw Manufacturing process 1.doc

- Screw Manufacturing process 2.doc

- Screw Manufacturing process etc. com

- Screw Manufacturing Process Validation .doc

- Manufacturing documents, screwdriver

- See Manufacturing Plan, ViperManufacturingPlan.doc

- Screwdriver Manufacturing process 1.doc

- Screwdriver Manufacturing process 2.doc

- Screwdriver Manufacturing process etc. com

- Screwdriver Manufacturing Process Validation .doc

- Manufacturing documents, system

- System drawings .doc

- label information .doc

- Final inspection protocol .doc

- Post-Market documents: Post-market plans and data for all components and accessories of the Viper plate are described in the following documents:

- Viper Post-Market Plan .doc

- Viper Post-Market Report .doc

- Clinical documents: Clinical data for all components and accessories of the Viper plate are described in the following documents:

- Viper Clinical-Data Plan .doc

- Viper Clinical-Data Report .doc

- Risk Management documents: Risk management plans and summaries for all components and accessories of the Viper plate are described in the following documents:

What’s required in technical documentation is clearly identified and listed in Appendix ???? of the EU-MDR. Simply copy what “shall” be included before adding what you think “should” or “could” be included.

Continuos Improvement

Lessons Learned

- Any acquiring company must either adhere to the plan or justify why they change it, and all changes must be maintained in their document system for future teams to access.

- Long-term efficiency improves with effective plans. Quick meetings are short-sighted; the time saved moving forward that week costs many months of inefficiency and miscommunications later.