Medical Device Design Controls

5 minute read.

This article provides an overview of FDA design controls and lists resources to help understand and apply them.

BACKGROUND

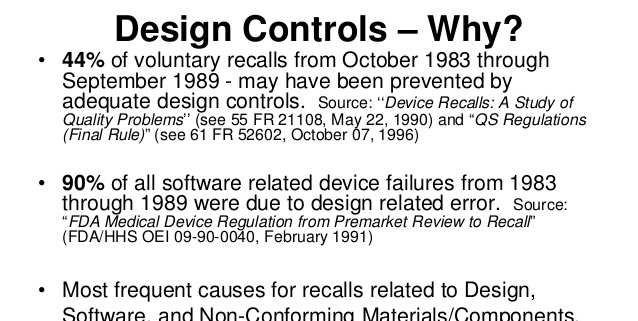

Researchers in the 1980’s discovered that 44% of medical device recalls in the United States could have been prevented through design controls.

Almost half of medical device recalls were preventable before a product was manufactured.

The risk to patients and cost to American medical device companies was addressed by the United States Food and Drug Administration. The FDA worked with industry experts to understand best-practices for effective and efficient design, adding Design Controls to recommended guidelines. In 1997, these guidelines became the FDA Quality System Regulation (QSR), a law under theCode of Federal Regulations, Title 21, part 820 (21 CFR 820).

OVERVIEW

FDA laws apply to any manufacturer of medical devices or pharmaceuticals selling products in the United States. Design Controls are one subsystem of a required Quality System.

Design Controls are not required when researching new ideas. Design Controls begin, and must be documented, when a company commits to developing a product. The distinction between research and development should be defined in each company’s Quality System.

Design Controls have ten components listed in 21 CFR 820.30, paraphrased below:

General Requirements 21CFR820.30 (a)

Use design controls. It’s required for all manufacturers of class Class II and Class III medical devices and a few Class I devices.

Design & Development Planning 21CFR820.30 (b)

Create and follow a development plan.List who’s responsible for all aspects of development and how teams interface.Update plans when necessary using a team-driven process.

Design Input 21CFR820.30 (c)

Inputs are what needs to be accomplished by a design, including regulatory requirements and business needs.

Inputs are not “designs,” inputs are what should be accomplished by a design to ensure user needs are met.

Inputs are agreed upon, in writing, by people listed in your plan.

Design Output 21CFR820.30 (d)

Outputs are design features that satisfy inputs.

Outputs are typically in the form of drawings, software, procedures, labels, and inspection criteria of features critical to satisfying Inputs.Outputs are reviewed and agree upon, in writing, by people listed in your plan.

Design Review 21CFR820.30 (e)

Reviews ensure plans are followed and updated using a team-driven process.Reviews shall have at least one person attending who does not have responsibility for the stage of your plan being reviewed.Reviews are approved, in writing, by people listed in your plan.

Design Verification 21CFR820.30 (f)

Verification compares outputs to Input requirements.

Verification must be measurable.For example, for an Input of “weighs less than 2.0 kilograms” the output could be verified by measuring weight on a scale.

Verification is reviewed and approved, in writing, by people listed in your plan.

Design Validation 21CFR820.30 (g)

Validation ensures Inputs are met for output that can not be measured.For example, measuring a mass-produced chemical wouldn’t be practical, output can tested using samples and validating consistency through statistics

Validation also ensures user needs are met from the user’s perspective.For example, if an Input is that a package “must be opened within 30 seconds” the final design couldn’t be measured directly, it must rely on real-world people in a controlled test.

Validation must use production-units in actual or simulated conditions.Validation is reviewed and approved, in writing, by people listed in your plan.

Design Transfer 21CFR820.30 (h)

Ensure that you can transfer a design to manufacturing without losing control of outputs that were verified and validatedTransfer is reviewed and agreed upon, in writing, by people listed in your plan.

Design Changes 21CFR820.30 (i)

Changes to inputs, outputs, and verification or validation methods must be controlled ensure there aren’t unforeseen consequences, including for other products that may share design componentsChanges are reviewed and agreed upon, in writing, by people listed in your plan.

Design History File 21CFR820.30 (j)A Design History File (DHF) is evidence that a product was developed according to a Plan, including references to the locations of all plans, inputs, outputs, verification, validation, and transfer procedures.

I emphasize that a DHF is also a history of “why” changes are made so that future teams learn from current teams. This has been critical in addressing device recalls and designing improvements.

Design Controls assume that teams document risk-assessments throughout development to minimize risk in designs and manufacturing processes.

Historically, a waterfall-diagram has been used to illustrate Design Controls.

Most companies don’t follow a waterfall-method for development. Design activities occur simultaneously, often across different teams that may reside in multiple states or countries. Modern companies also strive for concurrent-design between teams, such as development and manufacturing.

Design Controls may be simplified to documenting a process of creating and following a plan, focusing user needs and regulatory requirements to create inputs, facilitating communication between teams using change procedures & reviews, ensuring outputs satisfy Inputs through verification and validation prior to transfer, and documenting your process in a Design History File that includes assessments of risks and mitigations in both design and manufacturing.

Design Controls extend into manufacturing and throughout the life of a product. Feedback from manufacturing and post-market surveillance becomes input for design changes.

RESOURCES & NEXT STEPS

The FDA is a transparent organization. To paraphrase The Buddha, there isn’t a secret “hidden in the closed fist of the teacher.” The FDA tells you exactly what they require and tries to help you accomplish it. The resources below are focused on medical devices and Design Controls.

FDA OFFICIAL INFORMATION

FDA Quality System (QS) Regulation / Medical Device Good Manufacturing Practices21 CFR 820, printed version21 CFR 820, electronic version (e-CFR)FDA “Device Advice”

FDA Division of Industry & Consumer Education (DICE)

Includes phone numbers for conversations with real peopleGo ahead, roll the “dice” (I couldn’t resist)

FREE TRAINING

FDA Design Control Guidance for Medical Device ManufacturersFDA guidance on Design Controls (.pdf version)FDA presentation on Design Controls

FDA online training and continuing educationalmost overwhelming with the amount of information ranging from foods to drugs to devices – search for keywords

FDA Center for Devices and Radiological Health (CDRH) online training, “CDRH Learn”CDRH is the source for most medical device training

TRAINING & CONSULTING COMPANIES

SUMMARY

Design controls are laws to protect patient safety and facilitate efficient companies.Design Controls are a part of the FDA Quality System Regulations.Design Controls can be summarized as: Focus on solving user needs, follow a plan, ensure communication via design reviews, verify and validate that designs meet user needs, oversee successful transfer to manufacturing, and document all designs and changes in a Design History File.

FDA design controls are one part of selling medical devices in the United States. To sell in other countries requires additional requirements, including a comprehensive quality control system that meets FDA Quality System Regulations and the International Standards Organization standards in ISO 13485, plus each country’s specific requirements including the new

.

Good luck!